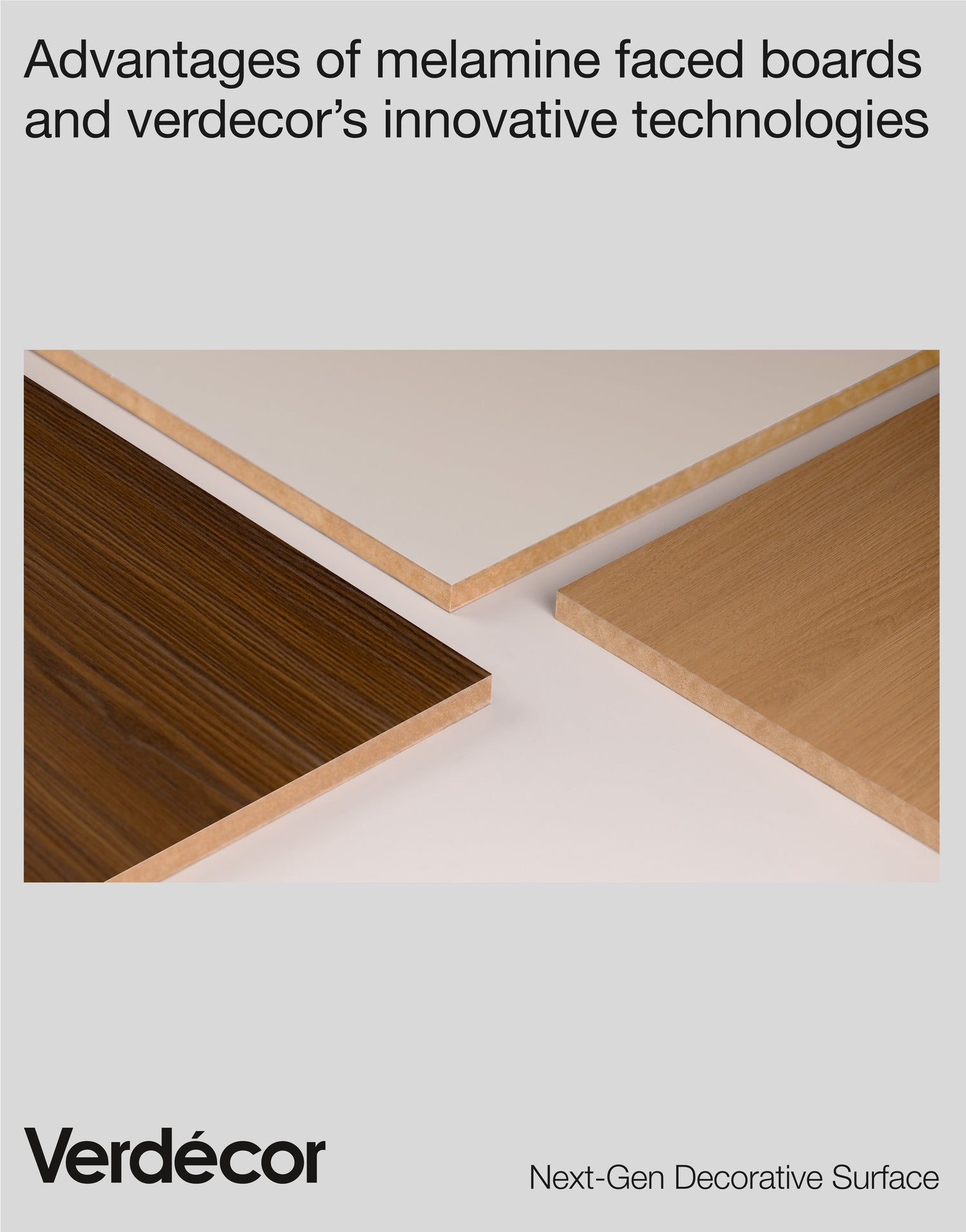

Melamine Faced Boards have long held a central position in the decorative panel industry due to their outstanding durability and aesthetic appeal. As a traditional and mainstream choice, they have proven their reliability over time. However, with consumers increasingly demanding higher-end finishes and eco-friendly materials, Verdécor has consistently pushed the boundaries of conventional melamine technology. Through innovative techniques and global supply chain partnerships, Verdécor has elevated the texture and performance of melamine-based products to an entirely new level.

Unparalleled Advantages of Melamine Faced Boards

-

Scratch Resistance

The surface of melamine boards undergoes high-pressure heat curing, forming a hard protective layer with exceptional scratch resistance. This makes MFB especially suitable for high-traffic furniture surfaces, such as kitchen countertops and cabinet doors. -

High Temperature Resistance

Melamine boards boast excellent heat resistance, withstanding short-term contact with hot objects (like pots or oven trays) without warping or damage—making them a top choice for kitchen applications. -

Moisture Resistance and Dimensional Stability

The dense surface layer of MFB effectively blocks moisture penetration. When paired with high-quality substrates, the board maintains its shape and stability even in humid environments. -

Variety of Designs

Melamine boards offer a wide range of colours, patterns, and textures through decorative paper—from natural woodgrains and stone effects to unique graphic designs—meeting the diverse needs of modern interior design. -

Cost-Effectiveness

As a highly economical decorative material, melamine boards are significantly more affordable than natural veneers or stone, while being suitable for large-scale production to meet mass market demands.

Verdécor’s Innovations in Melamine-Based Products

Although MFB is already a mature category, Verdécor continues to enhance its texture and performance through technological innovation and process improvements.

1. Special Coating with EB (Electron Beam) Technology

Building on traditional melamine processing, Verdécor integrates Electron Beam (EB) technology by applying a special coating to the board surface, which is then cured using EB treatment. This results in several performance upgrades:

- Yellowing Resistance: The high-density EB-cured coating resists discoloration over time, even under prolonged UV exposure, preserving a fresh appearance.

- Antibacterial Properties: EB coatings create a denser surface that inhibits the adhesion of bacteria and viruses, making it ideal for hygienic environments such as kitchens and medical facilities.

- Refined Tactile Finish: EB treatment delivers a matte or silky surface finish, enhancing the premium feel of the product.

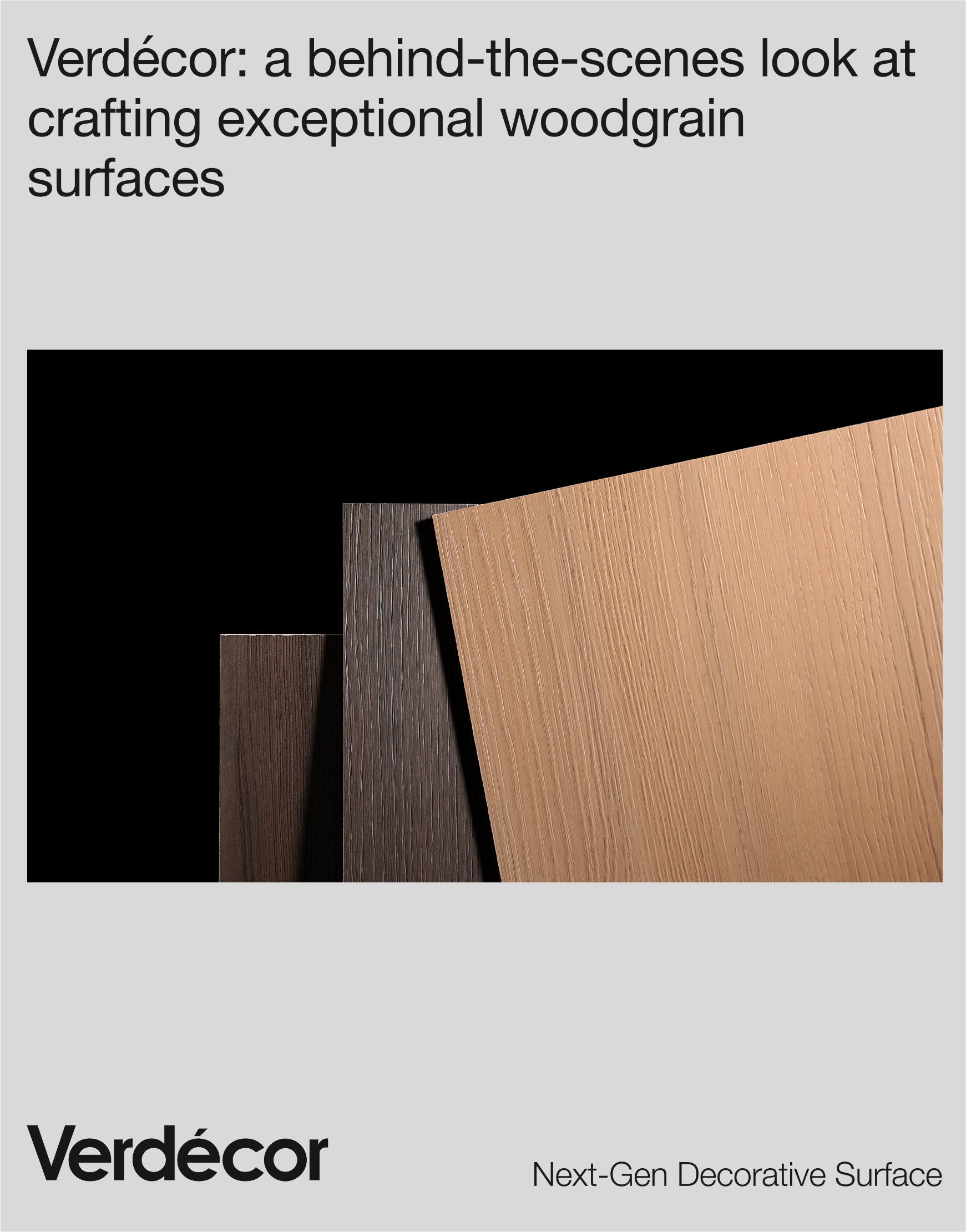

2. High-Precision Woodgrain Steel Plate Customization

To meet the demand for hyper-realistic woodgrains, Verdécor collaborates with Italian custom steel plate manufacturers to develop high-precision woodgrain plates. Using synchronized embossing technology, they align the decorative paper's grain pattern with the embossing to achieve perfect visual and tactile harmony. Key benefits include:

- Authentic Woodgrain Appearance: Achieves up to 95% realism, with natural-looking depth and contrast in every grain.

- Diverse Design Options: Custom plates can match a wide array of decorative papers, from classic walnut to modern oak, with precise reproduction.

3. Globally Advanced Automated Production Lines

Verdécor utilizes fully automated production lines from Germany and Italy, including pressing systems from Wemhöner, to ensure efficient and consistent panel manufacturing. This level of automation significantly minimizes human error, ensuring high-quality consistency across all production batches.

Melamine Process vs. Traditional Flat Lamination

Compared to traditional flat lamination (where melamine paper is glued directly to substrates), melamine technology demands a significantly higher standard of equipment, typically requiring:

- Hot Pressing Units: To fuse melamine paper and substrate under high heat and pressure, forming a dense surface layer.

- Automated Control Systems: To precisely regulate pressing time, temperature, and pressure, ensuring consistent quality.

- Synchronized Embossing Equipment: To align the decorative grain with the surface texture, creating a lifelike woodgrain effect.

Despite higher production costs, the durability and aesthetic value of melamine faced boards make them a premium choice in the market.

A Perfect Blend of Tradition and Innovation

As a leader in the decorative panel industry, Verdécor maximizes the advantages of traditional melamine boards through continuous innovation. From integrating EB technology with advanced coatings, to adopting high-precision steel embossing and global automated production systems, Verdécor not only enhances performance and visual appeal but also sets new standards for melamine boards in the high-end market.

Looking ahead, Verdécor remains committed to technology-driven development and sustainability, offering decorative materials that combine exceptional performance with distinctive aesthetics—shaping every space into a masterpiece.