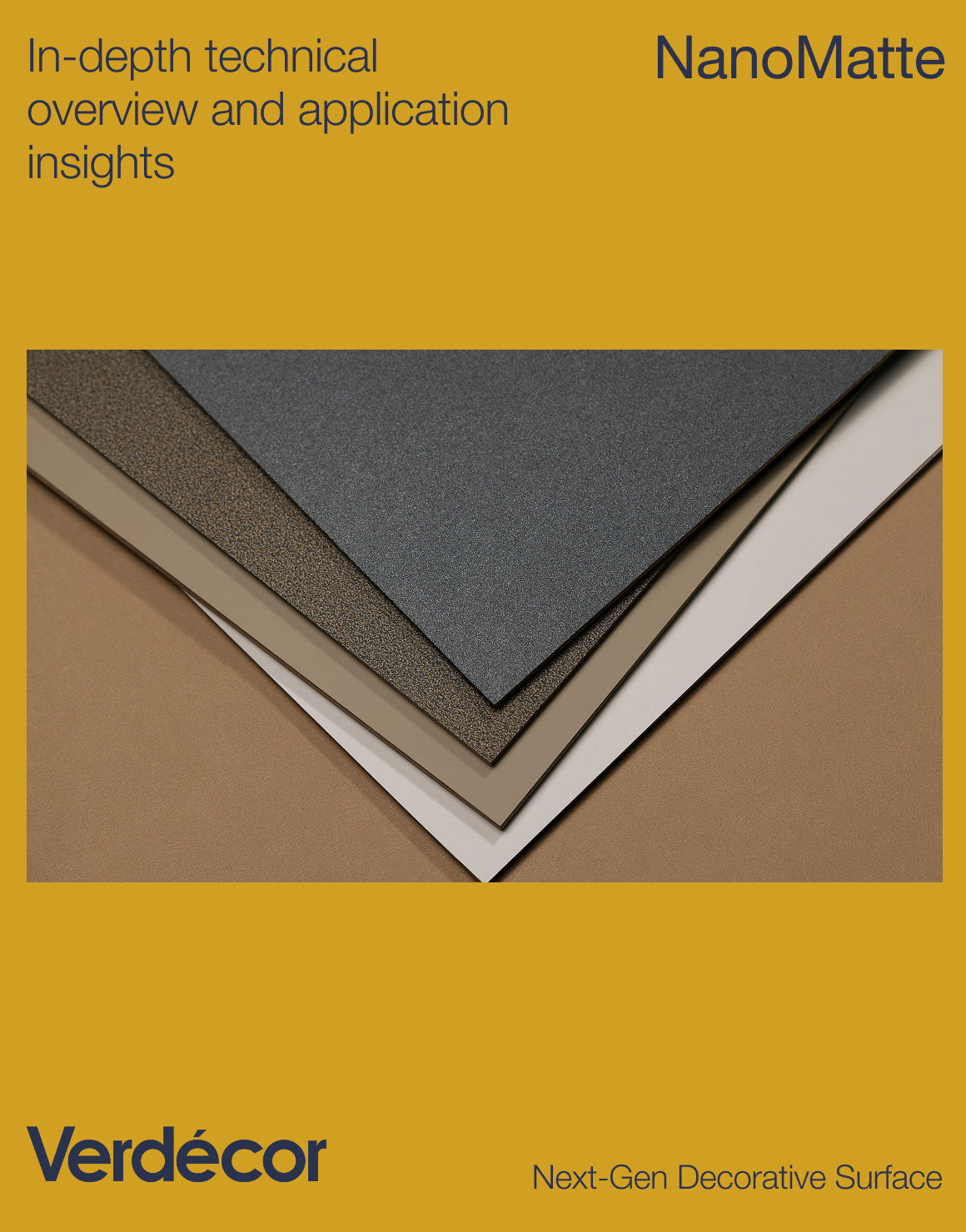

The NanoMatte collection sets a new benchmark in surface materials by combining advanced Electron Beam curing technology with a commitment to sustainability and durability. This state-of-the-art process ensures unparalleled surface characteristics, making NanoMatte an exceptional choice for modern interiors.

Advanced Technology: Electron Beam Curing

The NanoMatte collection employs Electron Beam curing technology, which uses high-energy electrons to create a densely cross-linked molecular network within the coating. This innovative curing process delivers several critical advantages:

- Complete Curing: Unlike traditional thermal or UV curing methods, EB curing ensures near-complete curing, resulting in a robust and uniform surface structure.

- Anti-Yellowing: By eliminating the need for photoinitiators, EB curing minimizes the risk of yellowing over time, preserving the material's aesthetic appeal.

- Eco-Friendly Process: This advanced curing method significantly reduces emissions of volatile organic compounds (VOCs), aligning with sustainable practices for modern interiors.

Exceptional Features: Merging Functionality with Aesthetics

The NanoMatte collection excels not only in appearance but also in performance, offering the following unique features:

Ultra-Matt Finish

NanoMatte’s low-reflective, velvety surface creates a luxurious and modern aesthetic. This matte effect is achieved through a densely cross-linked molecular structure, ensuring a soft, natural visual impact.

Fingerprint Resistance

The high-density molecular network minimizes the adherence of oils and moisture, making NanoMatte surfaces remarkably resistant to fingerprints and easy to maintain.

Thermal Repair of Micro-Scratches

NanoMatte features a thermal repair capability, allowing superficial micro-scratches to heal with the application of moderate heat, ensuring a long-lasting pristine appearance.

High Wear Resistance

The durable molecular structure created by EB curing provides excellent resistance to scratches and abrasions, ensuring the material remains intact under daily use.

Superior Hygiene

The dense surface minimizes microbial adherence, complemented by additional antibacterial properties, making it ideal for environments requiring high hygiene standards.

UV and colour Stability

NanoMatte surfaces demonstrate high resistance to UV exposure, preventing discolouration or aging even in bright, sunlit spaces.

Formaldehyde-Free MDF Core

All NanoMatte products use MDF base panels bonded with MDI adhesives, which are free from formaldehyde. Unlike traditional urea-formaldehyde adhesives, MDI forms a more stable and durable bond while completely eliminating formaldehyde emissions during and after manufacturing. This ensures that NanoMatte contributes to a healthier indoor environment and meets the stringent Japanese F**** certification standards for environmental safety.

Applications: Where NanoMatte Excels

NanoMatte surfaces offer a perfect balance of style and functionality, making them suitable for a variety of settings:

Residential Spaces

- Kitchens and Bathrooms: Fingerprint-resistant and easy to clean, NanoMatte is ideal for high-traffic, functional areas.

- Living and Bedrooms: Its luxurious matte texture enhances furniture and wall paneling with a modern aesthetic.

Commercial Environments

- Offices: The anti-glare and low-maintenance properties make NanoMatte a preferred choice for workspace surfaces.

- Retail Displays: NanoMatte’s premium look and resilience enhance the visual appeal and durability of retail furniture.

Hygiene-Critical Spaces

- Healthcare and Education: Antibacterial and VOC-reducing properties make NanoMatte suitable for hospitals, schools, and childcare facilities.

Sustainability Commitment

The NanoMatte collection integrates sustainability at its core. By using MDI adhesives in its MDF base panels and significantly reducing reliance on VOC-emitting curing agents, NanoMatte supports eco-conscious construction and design practices. Furthermore, its durability and low-maintenance properties contribute to a longer lifecycle, reducing material waste.